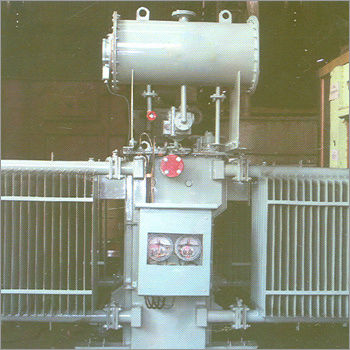

Power & Distribution Transformers

Product Details:

Product Description

Power & Distribution Transformers

A Transformer is a static piece of apparatus used for transferring power from one circuit to another without change in frequency. It can raise or lower the voltage with a corresponding decrease or increase in current.

The basic principal of a transformer is Faraday's Laws of Electromagnetic induction which states that whenever the flux linked with a coil changes an e.m.f is induced the transformer consists of a laminated iron core (Cold Rolled Grain Oriented Cor Lamination) about which are wound two or more sets of windings voltage is applied to one set of windings called the primary which builds up a magnetic flux through the iron secondary which limits the current e.m.f in the secondary which limits the current down from the supply.

MTPL transformers are designed and tested as per national and international standards I.e. IS: 2026, IS: 1180, IEC 76 BSI 171 ASA C57 other relevant IS and IE rules

WIndings

Electrolytic grade high conductivity Copper / Aluminium duly insulated with paper glass is used transformers

For better short circuit ability under fault conditions wound coils are pressed clamped and dried in oven prior to impregation in oil. Cooling ducts formed with rigid high density to spacers and horizontal and vertical ducts are provided to save hot spots.

Core Constructions

The core is designed with optimum flux density to minimize core loss and cost. Butt lap miter or step lap miter construction is chosen based on the application and core loss requirements.

Laminations are burr free and very thin between 0.23 mm and 0.30mm varying no more than ±0.05mm in length for the last lowest sound level and excitation currents Each lamination is covered with a high resistance inorganic coatings to reduce eddy currents.

The laminations are handled with minimum bending to preserve the low loss properties. The core is clamped in a rigid frame with uniform uniform pressure to reduce mechanical effect on performance.

Core and Coil Assembly

MTPL uses high electrical grade Kraft paper and press board as per IS: 1576 The insulating papers are checked for high dielectric strength good aging properties and moisture retardation Permali wood is also used in top and bottom for mechanical strength.

We use off circuit tap switches for general trasformers externally operated ON LOAD TAP CHANGER of OLG/CTR make for special transformers and frunace applications whereas EASUN - MR make INTANK type OLTC are used in Sub Merged Arc Melting Furnace Transformers as per customer's technical specification.

Tank

All our tanks are fabricated with high grade tested mild steel. The design of the tanks incorporate adequate wall and base thickness so as to withstand the pressure build up in the tank.

Welding is carried out in accordance with strict standards using jigs and fixtures to ensure dimension accuracy. Double weld are provided where oil tightness is required. All oil tight weld are tested to ensure no leakages occurs. Flat gasket of neoprene bonded cork sheets are used for joints and auxiliary fitments.

For ONAN Colling, Pressed sheet steel radiators are used for cooling ensuring that greater surface area is available for high dissipation. The radiators are independently pressure tested and then mounted on the tank.

For ONAF Cooling, Fans are mounted vertically near the radiators for their optimum use

For OFWF Cooling Heat Exchangers oil pumps oil flow meter water flow meter pressure meters diffrential pressure gauge is used to suit the losses of transformers at 150% loading conditions.

Each transformer tank is tested for leakage by filling them with oil and keeping then under pressure of 0.5 KG/Cm2 or above for several hours. With this test even minute leaks are detected

Painting and Finishing

All fabricated steel tanks internally and externally cleaned thoroughly of all scales and rust by sand blasting / shot blasting. A coat of Zinc chromate primer paint is immediately applied to all external surfaces. This anticorrosive paint has rust inhibitive properties and excellent chemical resistance. Two coats of glossy oil and weather resisting not fading paint of light grey Shade No 631 or ISS are then applied.

Oil

The insulating oil used is of low viscocity with good resistance to oxidation and formation of sludge and acids. Moisture content dielectric strength etc is determined and certified by conduct relevant testes. as per IS - 335/1993. Generally we use 'POWER OIL' make EHV grade Oil.

Testing

Our testing Lab is fully equipped with 300 KV High Voltage Test Set, Double Frequency Test Set (Upto 25 MVA, 132 KV), CT's and PT's to check Losses and Impedence 600 Amps, 3 Phase Variac for Power Supply, Resistance meter 3 Phase Ratio meter in addition to other normal testing instruments.

The list of routing test as per Clause No 16.1.2(Part1) of IS: 2026 of 1977 is as follows

- Measurement of winding resistance

- Measurement of voltage ratio and check of voltage vector relationship

- Measurement of impedence voltage (Principal tappings) and Load loss

- Measurement of No Load loss and current

- Measurement of Insulation resistance

- Dielectric Test and

- Test on On load Tap changers where appropriate.

Other Products in 'Transformers' category

An ISO 9001:2008 Certified Company

|